Planning has become more crucial than ever in today’s fast-paced and unpredictable world. With various factors influencing our lives and businesses, having a solid demand planning strategy can mean the difference between success and failure. Whether you’re a small business owner or a seasoned professional, understanding the intricacies of demand planning is essential.

In this article, we will delve into the world of demand planning, exploring its significance and providing valuable insights, expert tips, and actionable recommendations to help sellers navigate these turbulent times. We will also uncover the secrets to effective demand planning that can propel businesses forward and ensure long-term success.

The Definition and Types of Demand Planning

Demand planning, also known as inventory forecasting, estimates the future demand for a product or service. By meticulously analyzing historical sales data, market trends, customer behavior, and other pertinent factors, demand planning enables businesses to anticipate future demand for their products or services accurately.

Accurate forecasting ensures businesses meet customer demand while optimizing inventory levels. It involves analyzing data to identify patterns and adapt to dynamic conditions. With inventory forecasting, companies calculate the necessary quantities of different inventory types for future periods, avoiding excess inventory and stock-outs. By leveraging this proactive approach, businesses can efficiently fulfill customer orders and maintain a competitive edge.

There are four most-presented and most-used types of demand planning:

- Trend forecasting involves projecting potential trends by analyzing changes in product demand over time. However, it may only sometimes consider factors like seasonality or other irregularities in past sales data.

- Graphical forecasting utilizes visual representations of historical data, enabling the identification of patterns and adding trend lines. This approach helps uncover valuable insights that may have been missed without the graphical representation.

- Qualitative forecasting relies on focus groups and market research to gather data. Forecasters then develop models based on this qualitative information.

- Quantitative forecasting utilizes numerical data from the past to predict future demand. The accuracy of the forecast typically improves with more extensive data collection.

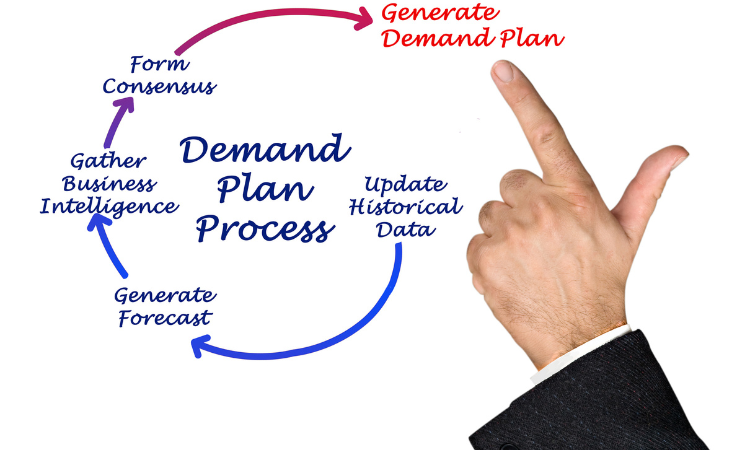

Demand Planning Process

A fundamental question to consider and get the proper answer to is: How do we determine what type of forecasting we should use? The answer to this is choosing what data can be gathered and considering whether the business is new or established.

Established companies often rely on historical data and conduct inventory analysis, favoring a quantitative approach. On the other hand, new companies typically begin by gathering qualitative market information.

The most effective forecasting methods involve a combination of different approaches and data types. Quantitative data provides a foundation for modelers, while incorporating qualitative data helps enhance and refine the model.

Benefits of Demand Planning

Demand planning offers various benefits that can positively impact a business:

Cost savings: By ordering the optimum amount of product, businesses can take advantage of bulk ordering while avoiding tying up unnecessary capital in excess inventory.

Customer and supplier satisfaction: Maintaining stock on hand helps keep customers satisfied and increases the likelihood of repeat business. Understanding supplier processes and timelines enables businesses to minimize stock-outs and maintain healthy supplier relationships, ensuring a smooth and reliable supply chain.

Back-end improvements: Effective demand planning and forecasting enhance supply chain management by proactively looking ahead to ensure the right amount of stock is available.

Strategic insights: By having a clear understanding of demand patterns and trends, businesses can make informed decisions regarding pricing, promotions, and resource allocation, leading to improved profitability and competitive advantage.

Inventory forecasting involves a systematic process businesses follow to predict their needs accurately. The first step is establishing a starting data point, often the baseline demand, which is the initial quantity of units for the forecasting model. Next, companies must consider various trends and variables impacting sales, such as promotions, marketing activities, and industry forces, including competitors and supply chain issues. Seasonality and the potential influence of fads or unpaid publicity, particularly from social media, should also be considered.

Once these factors are considered, businesses can build their forecasting models. This entails cleaning the data by removing any unusual or outlier data points and filling in missing information. A suitable statistical approach, either parametric or nonparametric, is then chosen to estimate the model parameters. The data is processed by loading and arranging it in a format appropriate for the selected algorithm. Regular validation and adjustment of the model are essential to ensure its accuracy.

Finally, businesses should continuously re-forecast based on new information and updates to make informed inventory management and supply chain optimization decisions.

How to Succeed With Inventory Forecasting?

Inventory forecasting is crucial in finding the right balance between having excess cash tied up in inventory and ensuring sufficient stock to meet customer demand. When conducting inventory forecasting, companies must consider three key factors:

Forecast period: The accuracy of a forecast decreases the further out it extends. Typically, companies use standard intervals such as 30 days, 90 days, or one year to project future demand.

Base demand refers to the known customer need at the start of the forecasting process. It is often determined by analyzing the prior 30 days of sales data or any pre-sales information available.

Application of variables and trends: Analysts must consider factors such as sales velocity, supply chain challenges, and seasonality when planning demand. Each industry has unique variables that impact demand, which must be carefully accounted for during the forecasting process.

Some of the best practices for successful demand planning are:

- Developing a collaborative team for forecasting.

- Implementing an effective inventory management program with documented processes.

- Monitoring inventory turnover and benchmark achievement closely. Incorporate qualitative data for forecasting decisions. Utilize all historical supply and demand data available.

- Analyze past margins and profits, and set future goals like gross profit margin. Applying the reorder point formula for inventory management.

- Thoroughly assessing sales trends for precision and accuracy. Leveraging lead time to enhance demand understanding.

- Calculate and maintain safety stock and utilize suitable software to support forecasting requirements.

Key Takeaways:

- Demand Planning Importance is essential for success in today’s unpredictable business landscape.

- Types of Demand Planning involves estimating future demand using four main types: trend, graphical, qualitative, and quantitative.

- Demand Planning Process: Method choice depends on data availability and business maturity; a practical approach combines quantitative and qualitative methods.

- Benefits of Demand Planning: Drives cost savings, customer satisfaction, and strategic insights.

- Success in Inventory Forecasting balances cash flow with customer demand, considering forecast period, base demand, and variables.

In summary, effective demand planning is essential for businesses thriving in today’s dynamic market. Implementing strategic inventory forecasting positions companies to meet consumer demands efficiently, optimizes inventory, enhances customer and supplier relationships, and drives operational and cost efficiencies. Combining analytical approaches with strategic planning allows businesses to navigate market complexities, achieve cost savings, and secure a competitive advantage. Embracing demand planning is critical to achieving long-term success and resilience in commerce, regardless of business size or industry.

Keep up with the latest Amazon and Walmart news updates and subscribe to our BellaVix newsletter 👇👇👇